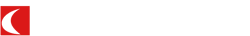

Edge pressing

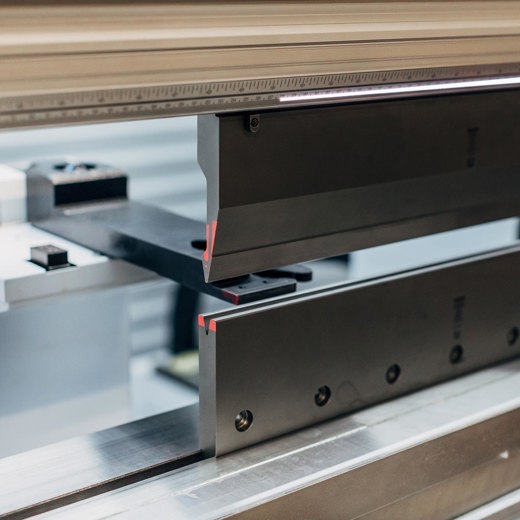

Edge pressing is a bending process that we perform manually on flat blanks that have first undergone laser cutting or punching. When they are then to be shaped into a specific part, they need to be bent or bowed at different angles. This is done through edge pressing or, as we call it, manual bending.

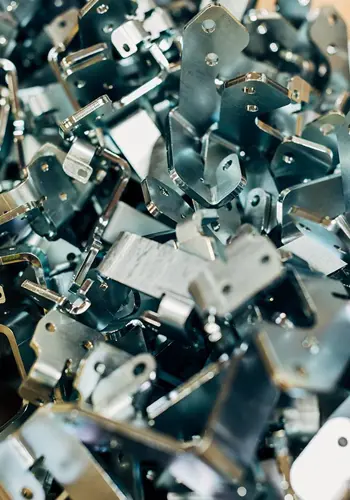

It is a good idea to bend advanced products or large parts in our manual edge presses, where we have a high degree of flexibility. We are able to bend parts that measure up to 4 meters. All of our manual bending machines are equipped with laser angle measurement, which means that they satisfy extremely stringent quality requirements. When the edge press and laser angle measure work in tandem, the results are perfect right from the first piece. This saves a lot of time and significantly reduces wastage. If you have a large recurring series that requires the use of robotic bending, we are in close contact with Rotage, who can take care of it.

Would you like to find out more about how we can bend your parts to perfection in the most cost effective way possible?

We produce a turnkey solution based on your requirements!

Need help optimizing your manufacturing?

Don’t hesitate to get in touch to discuss your questions and requirements. Our production engineers will gladly share their knowledge and experience to find a turnkey solution that will streamline and improve your production.